High Speed 6 Color Printing Machine is a printing machine that uses a photosensitive resin soft plate as a printing plate material, usually called a “flexo printing machine.” Suitable for printing polyethylene, polypropylene plastic bags, cellophane, roll paper and other packaging materials. It is an ideal printing equipment for food paper packaging, supermarket handbags, vest bags, clothing bags, etc.

Technical Data:

| Model of Machine | YT-6600 | YT-6800 | YT-61000 | YT-61200 | |||||

| Max.Width of Printing Material | 600mm | 800mm | 1000mm | 1200mm | |||||

| Max.Printing Width | 560mm | 760mm | 960mm | 1160mm | |||||

| Length Range of Printed Product | 191-1200mm | 191-1200mm | 191-1200mm | 191-1200mm | |||||

| Max.Diameter of Roll Material | φ450mm | φ450mm | φ450mm | φ450mm | |||||

| Printing Speed | 70m/min | 70m/min | 70m/min | 70m/min | |||||

| Accuracy of Registration | ±0.25mm | ±0.25mm | ±0.25mm | ±0.25mm | |||||

| Thickness of plate(Including Two-sides Glue Paper) | 2.38mm | 2.38mm | 2.38mm | 2.38mm | |||||

| Total Power | 10kw | 10kw | 11kw | 11kw | |||||

| Weight of Machine | 3500kg | 4200kg | 5000kg | 5500kg | |||||

| Overall Dimensions(mm) | 5500×1660×2950 | 5500×1860×2950 | 5500×2060×2950 | 5500×2260×2950 | |||||

Standard Unwinder& Rewinder Part:

1,Double Unwinder & Rewinder: easily to change rolls and save time | ||

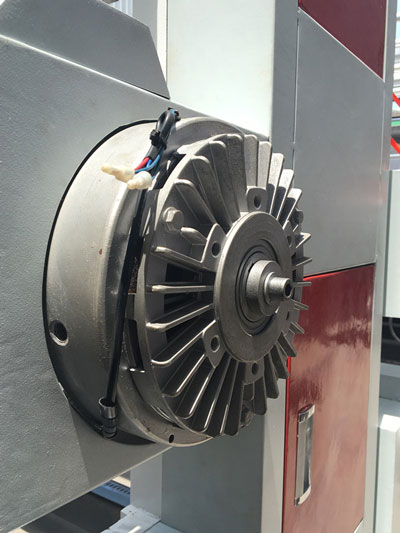

| 2, Automatic tension Brake 5kg | ||

| ||

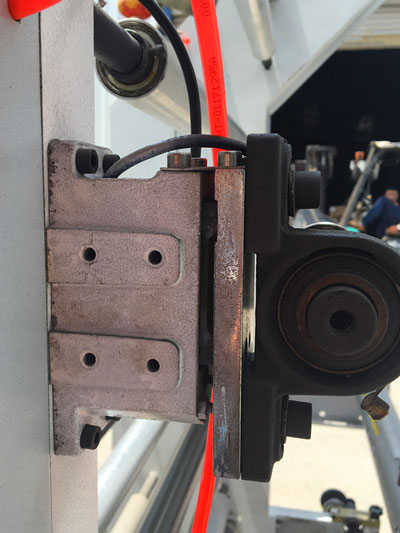

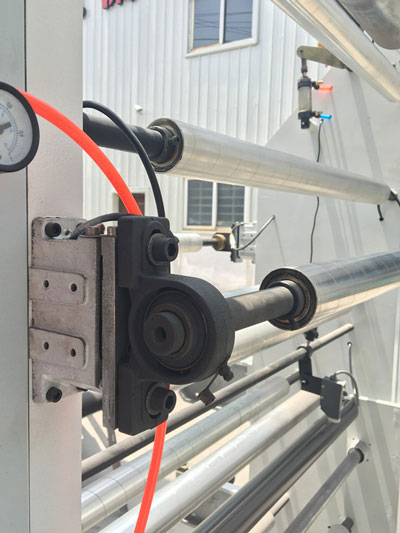

| 3, Tension sensor | ||

| ||

| 4, Auto Tension Controller It is automatic change hte tension according the tension of film | |

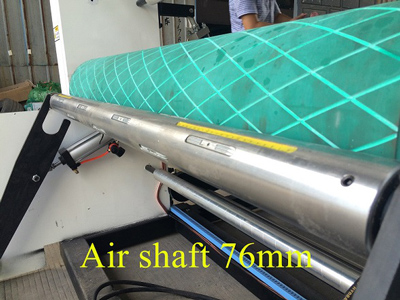

| 5, Air shaft: 76mm diameter for unwinder and rewinder, Which is easy to change rolls | |

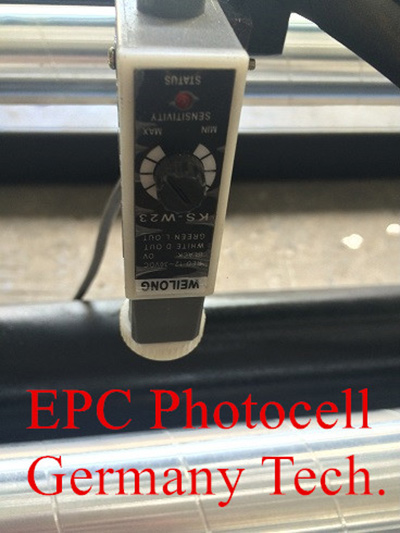

| 6, EPC Motor It can adjsut very accurate and make the printing materials more even | |

| 7, EPC Sensor Best quality in China. Very accurate | |

Printing Part:

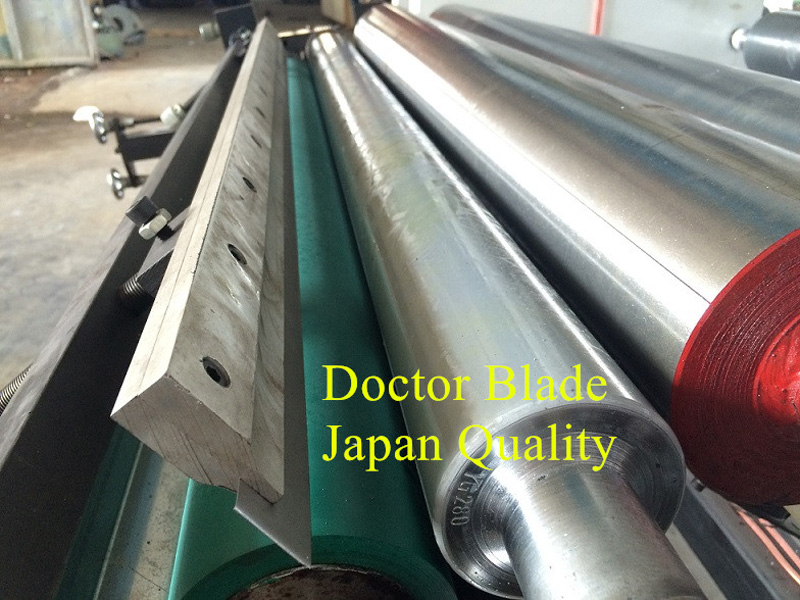

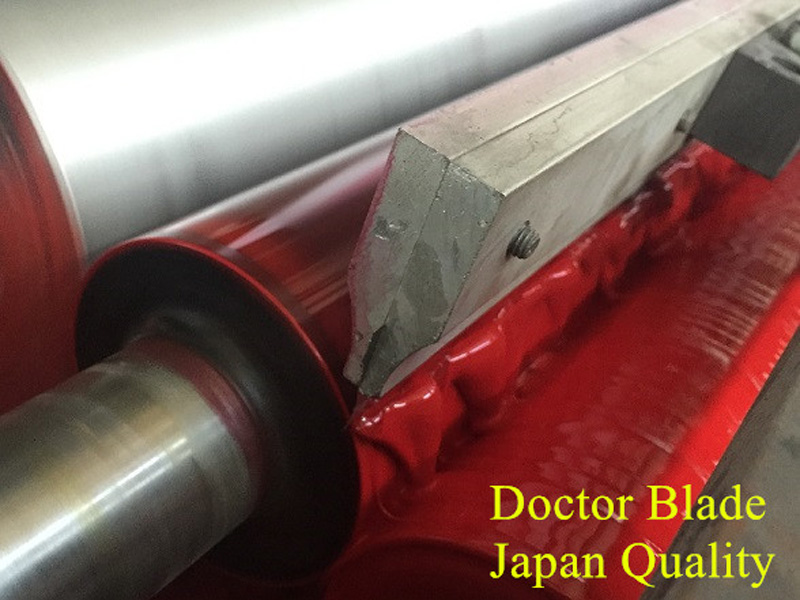

1, Doctor Blade: We use Metal Blade which can make the ink more even on anilox roller.  | |

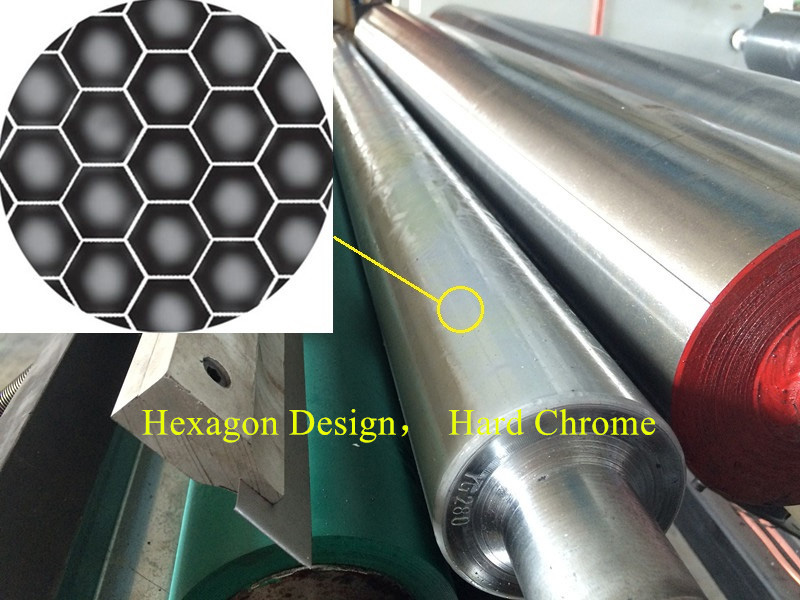

2, Anilox Roller: Steel anilox roller can do Max 320LPI, and Hexagon Design, so it can put max ink in dot. Anilox roller is designed by printing pictures. | |

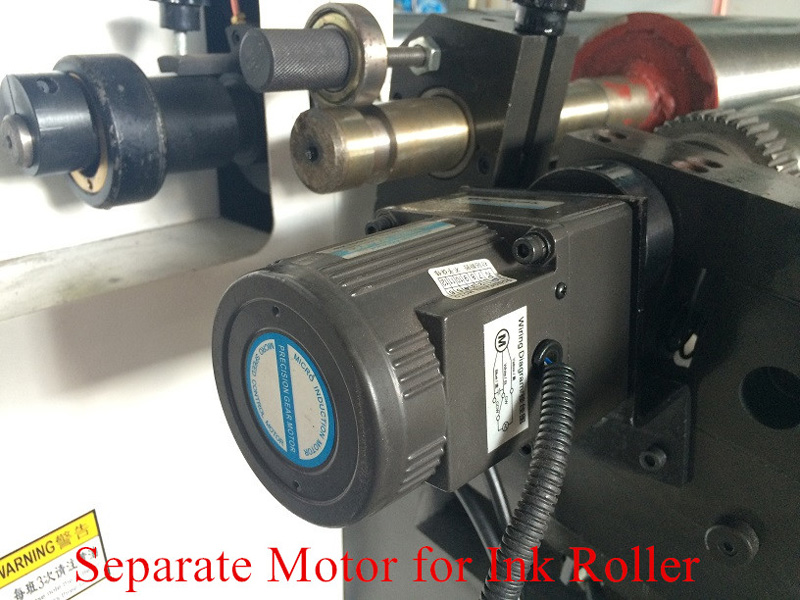

3,Separate Motor for Ink Roller. It will automatic running when machine is stop, and it can keep the ink running. No dry for ink | |

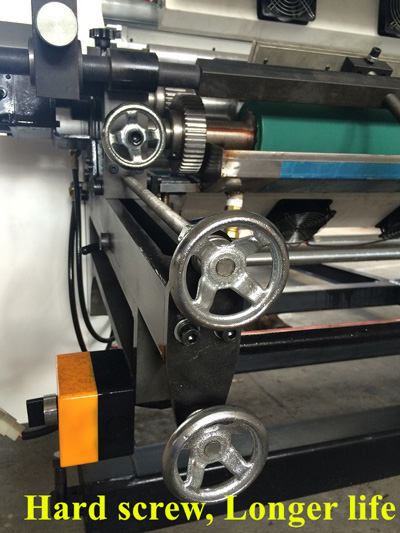

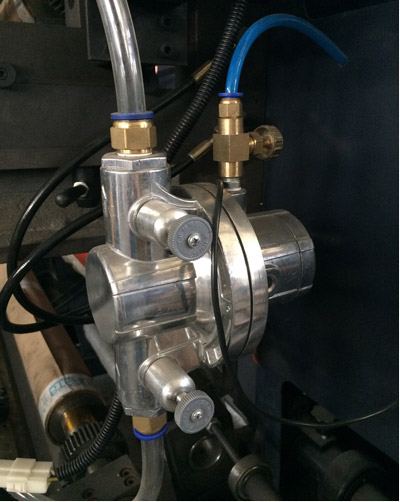

4, Adjust Bar: Stronger steel as bar. | 5, Ink pump : No need worker to add ink |

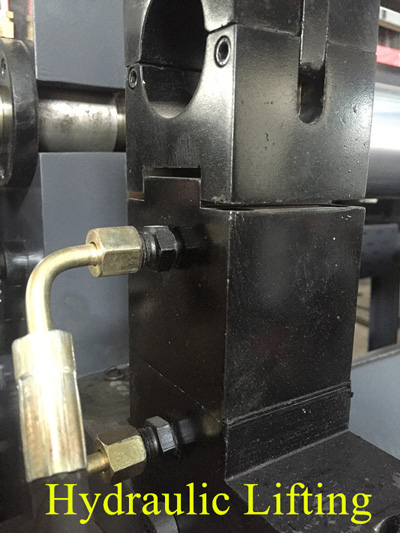

| 6, Oil Lubrication System, it can make machine running low noise and smoothly.  | 7, Hydraulic Lifting System, which is more stable than pneumatic, |

Transfering parts:

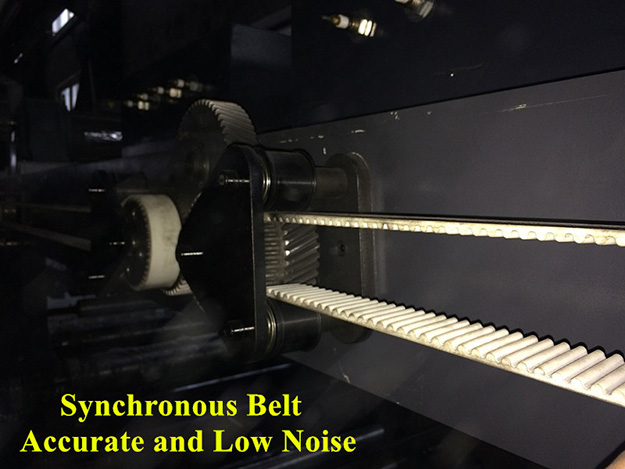

| 1,Synchronous BeltIt make the printing precision to 0.25mm and make machine running low noise |

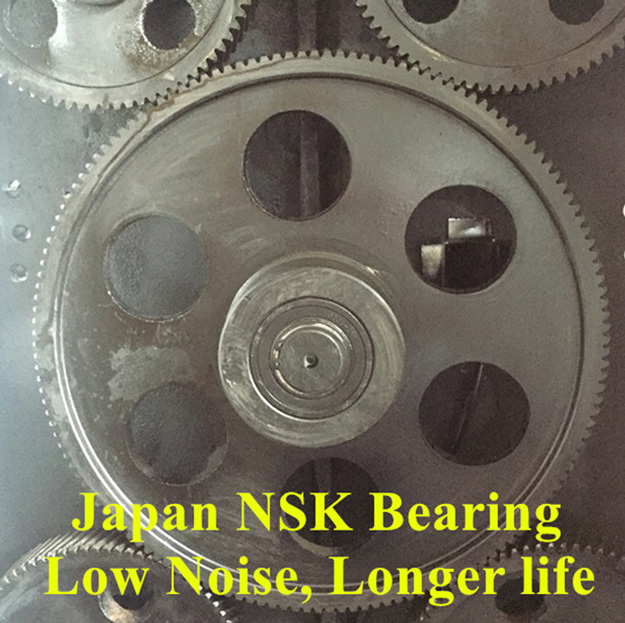

| 2, Helical Gear Very hard.It is with high precision helical gear, which make high quality printing performance. |

| 3, NSK BearingBest Brand in Japan, longer life to more 10 years |

Drying Parts:

| 1, Separate Heating drying It make each printing ink dry faster. |

| 2, Up Drying System, with hot and cold drying parts. So whole machine can run 70m/min and the printing ink can dry with good condition. | |