Optimized feature:

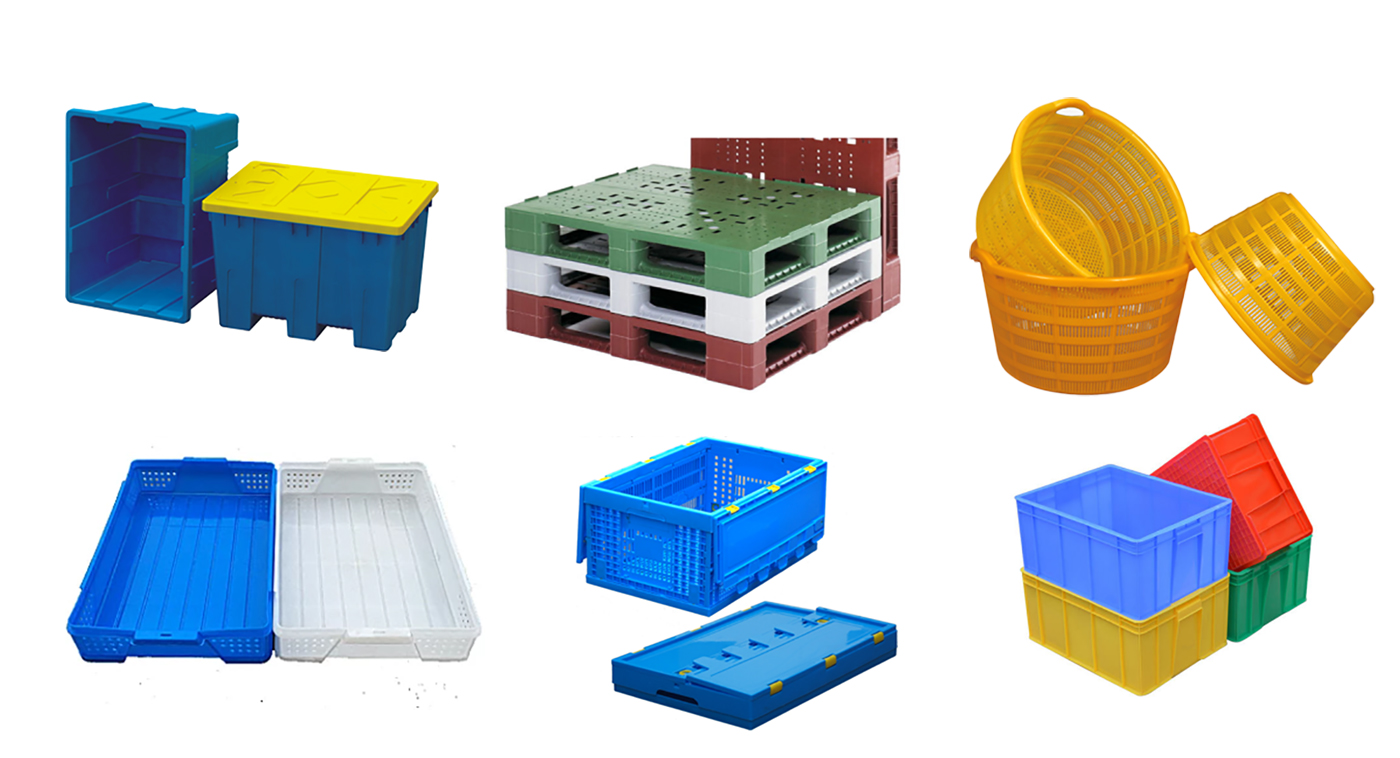

1.Enlarged motor & pump system, optimized hydraulic system to satisify high-performance with quicker cycle. Like crate(less than 2kg) cycle time20S;

paiting bucket(780-800g) cycle time 20S.

2.Specially designed screw and barrel with structure of quicker plasticization, shorten the material charging cycle.

Optional with bi-metal screw and barrel to compatible with recycling material for crate.

3.Optional with automatic facilities to improve the production efficieny.

Product Details

| MODEL: HXM368-G | |||

| TECHNICAL PARAMETER TABLE | |||

| INJECTION UNIT | SCREW DIAMETER | mm | 80 |

| SCREW L/D RATIO | L/D | 19 | |

| INJECTION CAPACITY IN THEORY | cm3 | 1709 | |

| INJECTION WEIGHT(PS) | g | 1555 | |

| oz | 54.8 | ||

| INJECTION PRESSURE | MPa | 131 | |

| INJECTION RATE | g/s | 583 | |

| PLASTICIZING CAPACITY | g/s | 80 | |

| SCREW SPEED | rpm | 160 | |

| CLAMPING UNIT | CLAMPING FORCE | KN | 3680 |

| MOVING MOULD-PLATE STROKE | mm | 710 | |

| MAX. MOULD HEIGHT | mm | 750 | |

| MIN. MOULD HEIGHT | mm | 250 | |

| SPACE BWTWEEN TIE-BARS (W×H) | mm | 720×690 | |

| HYDRAULIC EJECTOR FORCE | kn | 134 | |

| HYDRAULIC EJECTOR STROKE | mm | 180 | |

| Ejector number | n | 13 | |

| OTHERS | PUMP PRESSURE | MPa | 17.5 |

| MOTOR /DRIVING POWER | KW | 40 | |

| HEATING CAPACITY | KW | 25 | |

| MACHINE DIMENSION (L×W×H) | m | 7.4×1.99×2.24 | |

| MACHINE WEIGHT | t | 11.5 | |

| OIL TANK CAPACITY | L | 680 | |